Section Sampling and Accurate Costing

Updated October 19, 2017

This article applies to:

- Softree Optimal

Cost calculations are dependent on the spacing of sampled cross sections; if the spacing is too large (there are too few cross sections calculated) then the volumes will be inaccurate. Softree Optimal, RoadEng® (and other civil software) calculate volumes by sampling cross sections so you should be familiar with the concept of accuracy increasing with sampling frequency.

Ideally, you would like to obtain a cost for any given alignment that would not be affected by the choice of the sections. Softree Optimal provides a procedure that helps determine an appropriate section spacing to determine an accurate cost.

First let’s experiment and see how section spacing affects the cost calculation.

- Open the Softree Optimal

application.

application. - File button | Open. Select Hart Rd.dsnx. Press Open.

- Arrange your screen as before. You may need to arrange your visible windows by selecting the View tab | Tile Vertically

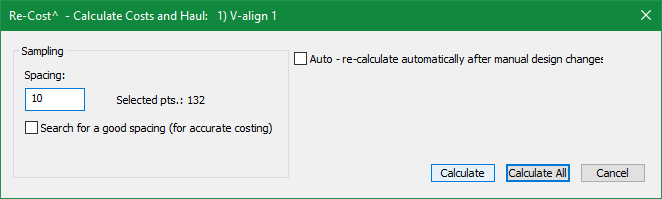

- Press the Re-Cost^ button in the Alignment Properties panel.

- Type 10 in the Spacing edit box. Press the Calculate button.

Figure 1: The Re-Cost dialogue box.

Note the calculated cost values in the information area.

- Repeat the Re-Cost^ operation for spacing values of 5, 2, and 1.

The results are shown in the table below:

| Spacing | Total Cost | Cut Cost | Fill Cost | Haulage Cost |

|---|---|---|---|---|

| 10 | 473.95 | 383.19 | 56.36 | 34.40 |

| 5 | 474.98 | 384.04 | 56.39 | 34.56 |

| 2 | 475.12 | 384.13 | 56.37 | 34.62 |

| 1 | 475.14 | 384.15 | 56.37 | 34.63 |

Table 1: Costs as a Function of the Sample Spacing

Observe that the costs vary (in this case very slightly) with the spacing. This means that the spacing we have chosen is already fine enough. Also, note that each calculation took a little longer than the previous.

Softree Optimal has automated the procedure for finding a fine enough spacing for accurate costing; it will automatically find a reasonable spacing so that the costs are unlikely to change by more than 1% when adding more cross sections. This procedure will be referred to as accurate costing.

- Press the Re-Cost^ button again. Check Search for a good spacing (for accurate costing). Press the Calculate button.

Softree Optimal returns with the following message:

Figure 2: Recommended Spacing

Softree Optimal suggests using 5.0 for the spacing.

- Choose Yes to close the message and set the sample spacing.

- Press the Re-cost button to view the dialog box one more time.

The sample spacing has been set to the new value.

- You can continue on to the next example, or press Cancel and Home button | Exit. Do not save changes.

Note: It is suggested that you perform an accurate costing at the start of every project.

External Material Movement Example

Material Movement Types

While calculating a cost for your alignment, Softree Optimal is also generating an optimal haul specification. Because you can specify borrow and waste pits, there are two types of haul available:

- Internal haul moves material from excavation in the road construction area to embankment also in the road construction area.

- External haul is earthwork which either starts or ends up in pit (outside the road construction area).

All material movement is classified as either Freehaul, Overhaul or Endhaul depending on the haul distance.

External material movement includes the following types of movement:

| Borrow / Waste | Material movement from/to user defined pits. |

|---|---|

| Sidecast | Excess cut material disposed of along the alignment. |

| Overflow / Underflow | This movement is used only when all other options to balance volumes have been exhausted. The Overflow/Underflow pit is located at the beginning of the alignment. |

Note:

a) Softree Optimal must account for all material of each type. The sum of all Internal and External Material must be zero for all material types (cut and fill have opposite signs).

b) If you want to internally balance a road, remove all Borrow and Waste pits. If it is geometrically possible (without violating constraints), the road will be balanced internally (material movements will be restricted to the road construction area). If a significant volume ends up in Overflow / Underflow, it indicates a balance can't be made without importing or exporting material.